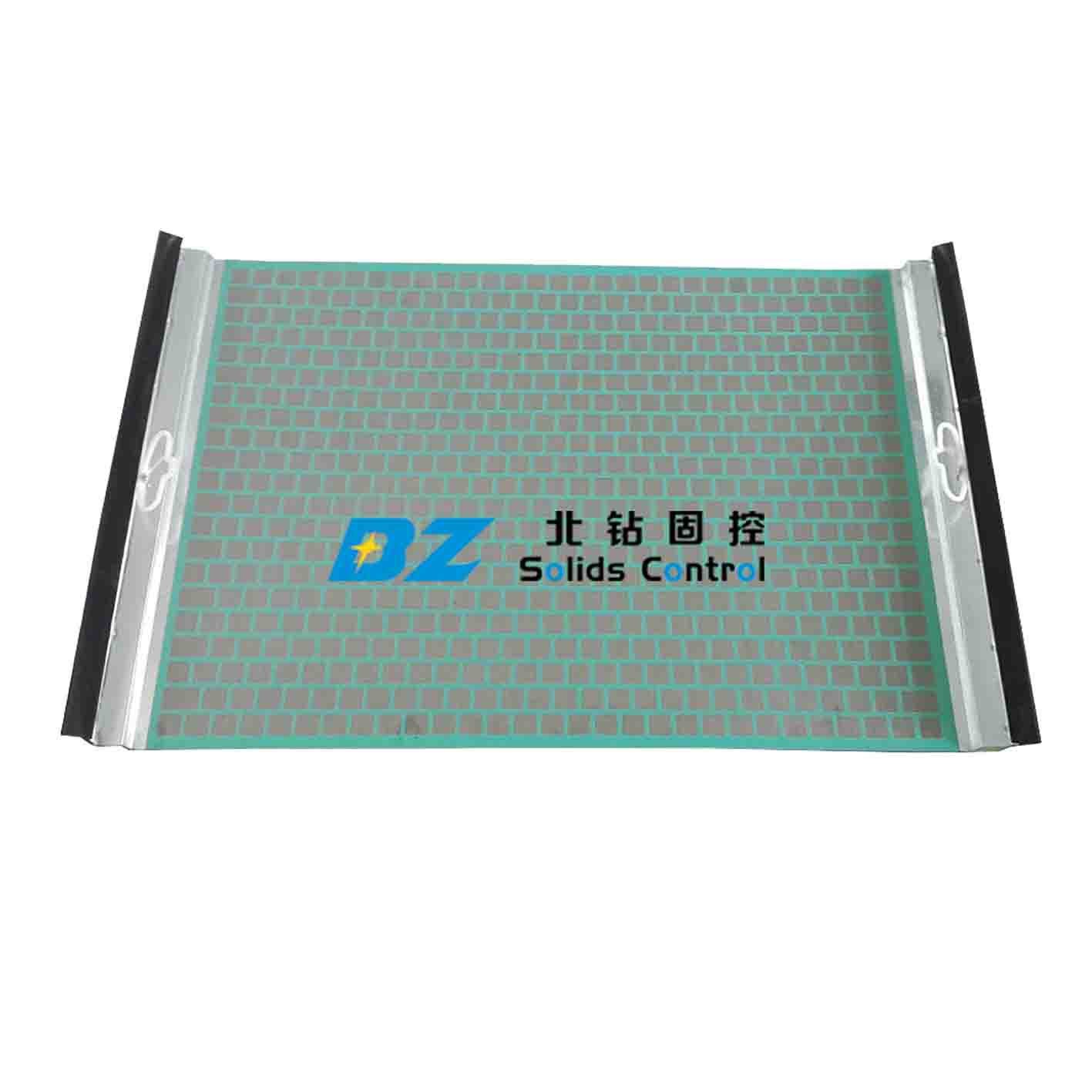

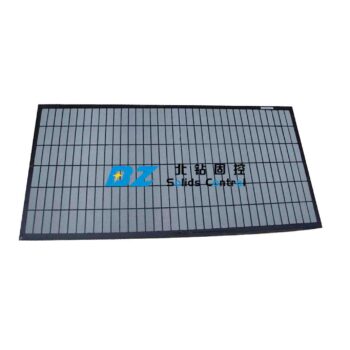

Flat replacement Shaker Screen

Description

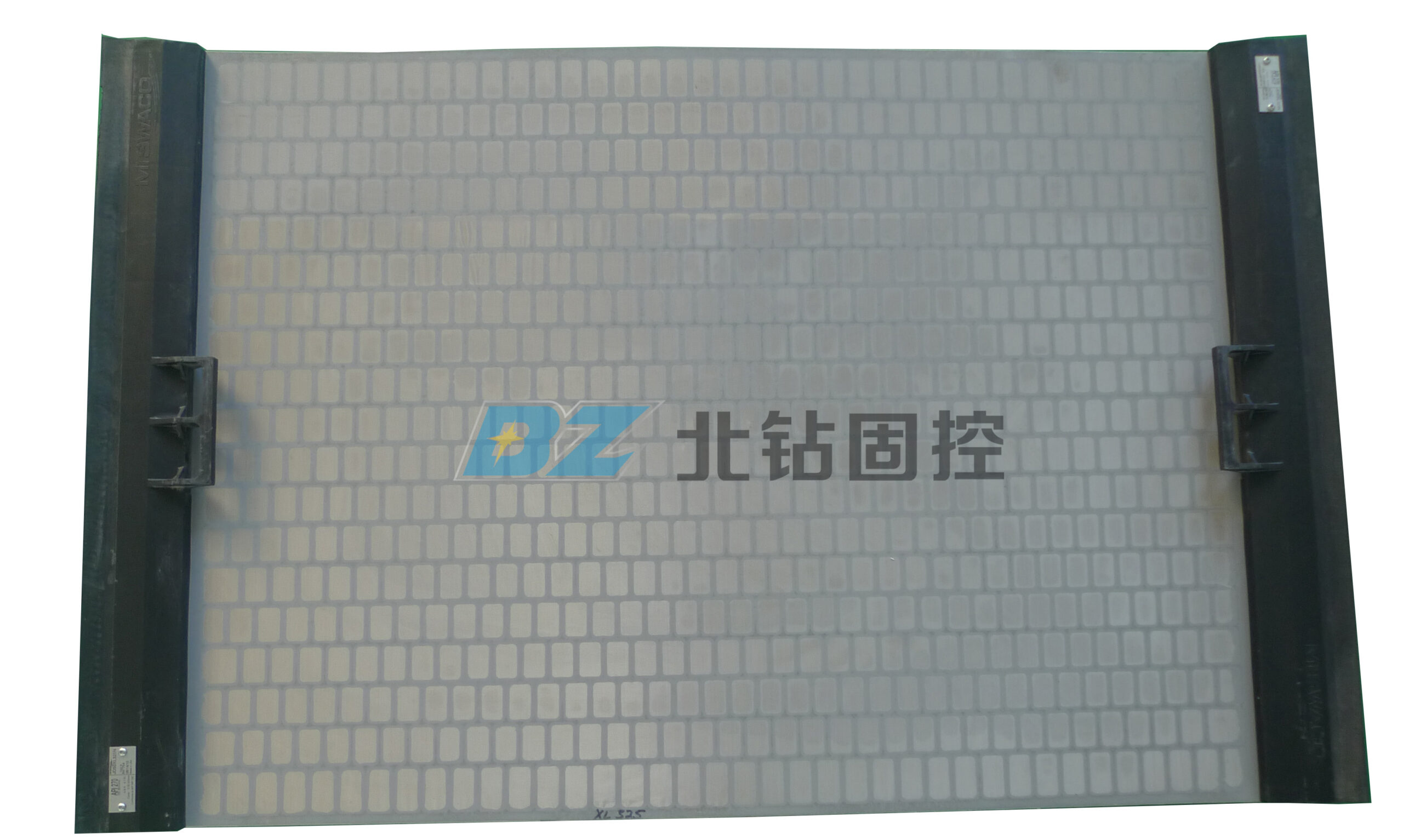

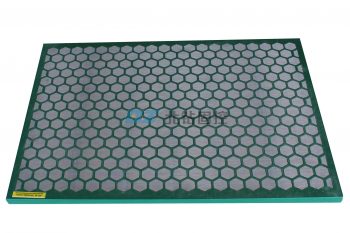

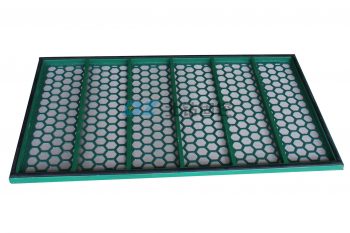

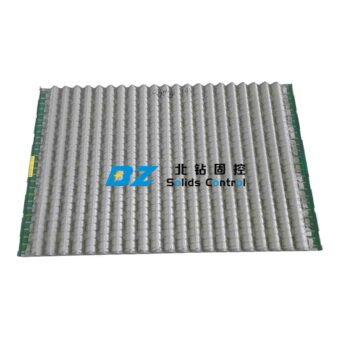

Flat replacement Shaker Screen is the most commonly used oil vibrating screen net, can be widely used in different conditions of drilling operations, plate hook edge screen is usually composed of 2 to 3 layers of stainless steel mesh bonded on the metal lining plate.

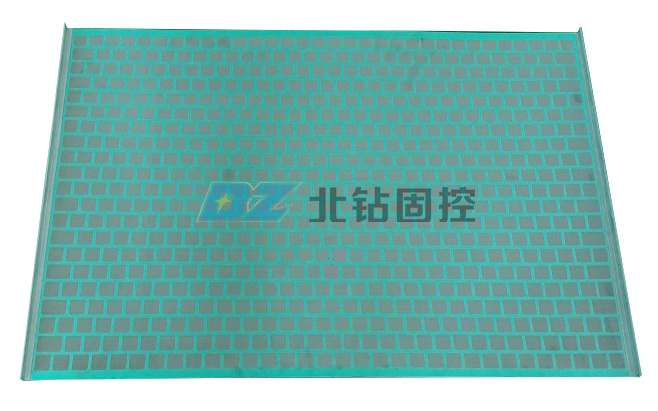

BZ flat-edge screen advantages and features:

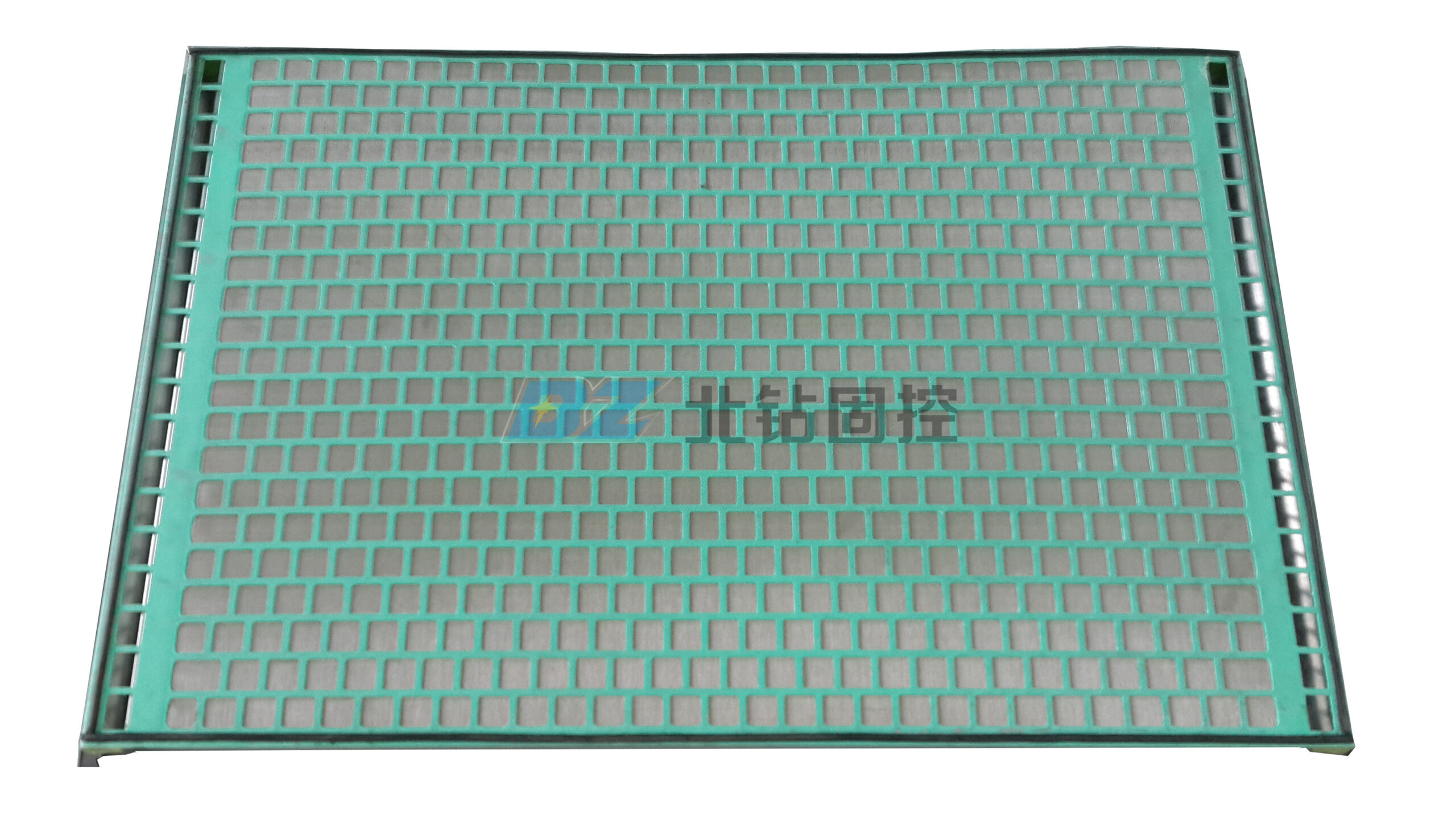

1. The meshes of each layer of mesh are different, and accurate and reasonable matching can make the screening effect more detailed. The meshes of the mesh are different and the punching shape of the metal liner And the size of the open porosity, under the premise of ensuring the strength of use, strive to obtain the largest effective filter area.

2. The stainless steel mesh cloth and the metal liner are tightly bonded together to enhance the strength of the entire screen. The entire screen is divided into multiple different independent small mesh surfaces to prevent local excessive damage and prolong the use time.

3. The mesh of the metal liner divides the mesh into multiple independent small mesh surfaces, which can prevent local damage from excessively expanding. At the same time, it is equipped with a special rubber race to repair the damaged mesh surface, which can save time and reduce the cost of use.

| Mesh | Dimension | Adaptation model |

| 20-325 | 697×1053mm | FLC2000 |

| 20-325 | 695×1050mm | FLC500 |

| 20-325 | 697× 846 mm | FLC313M |

| 20-325 | 1212×1141mm | ALS |

| 20-325 | 915×1150mm | LCM-2D |

| API Size Parameters | |||

| API Numbe | D 100 Separation(Micron) | API Number | D 100 Separation(Micron) |

| API 20 | >780.0 TO 925.0 | API 100 | >137.5 TO 165.0 |

| API 30 | >550.0 TO 655.0 | API 120 | >116.5 TO 137.5 |

| API 35 | >462.0 TO 550.0 | API 140 | >98.0 TO 116.5 |

| API 40 | >390.0 TO 462..0 | API 170 | >82.5 TO 98.0 |

| API 50 | >275.0 TO 390.0 | API 200 | >69.0 TO 82.5 |

| API 60 | >213.0 TO 275.0 | API 230 | >58.0 TO 69.0 |

| API 70 | >196.0 TO 213.0 | API 270 | >49.0. TO 58.0 |

| API 80 | >165.0 TO 196.0 | API 320 | >41.5 TO 49.0 |