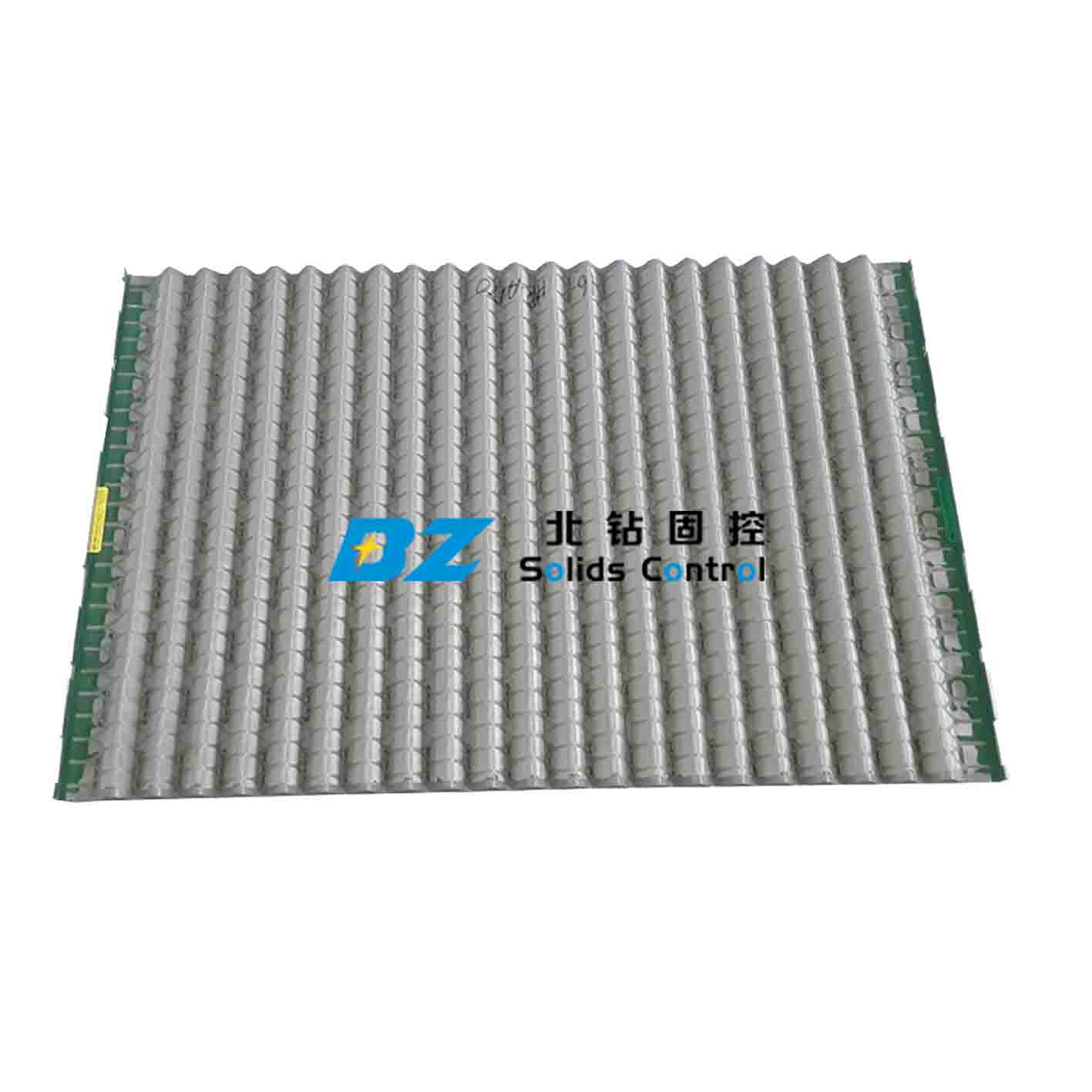

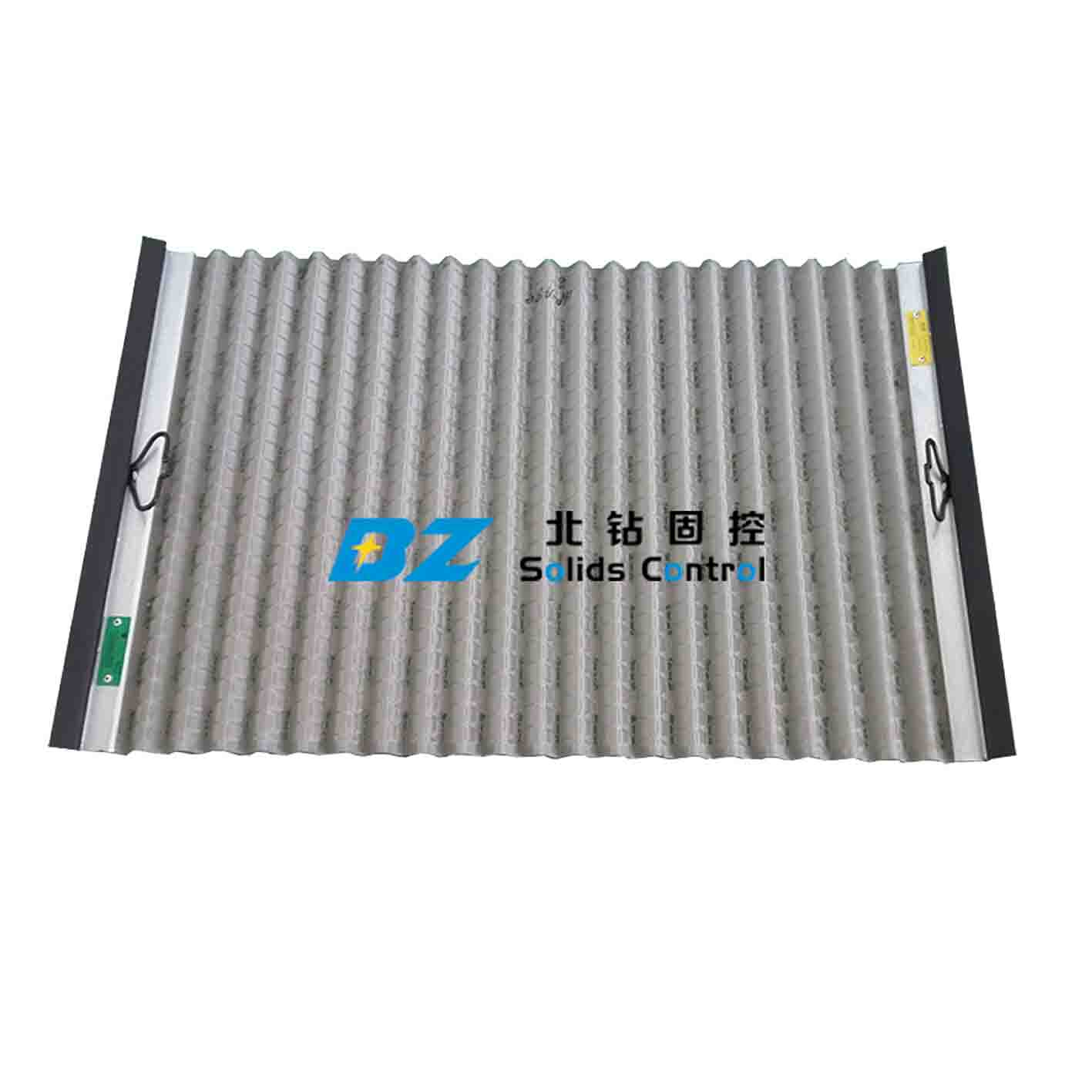

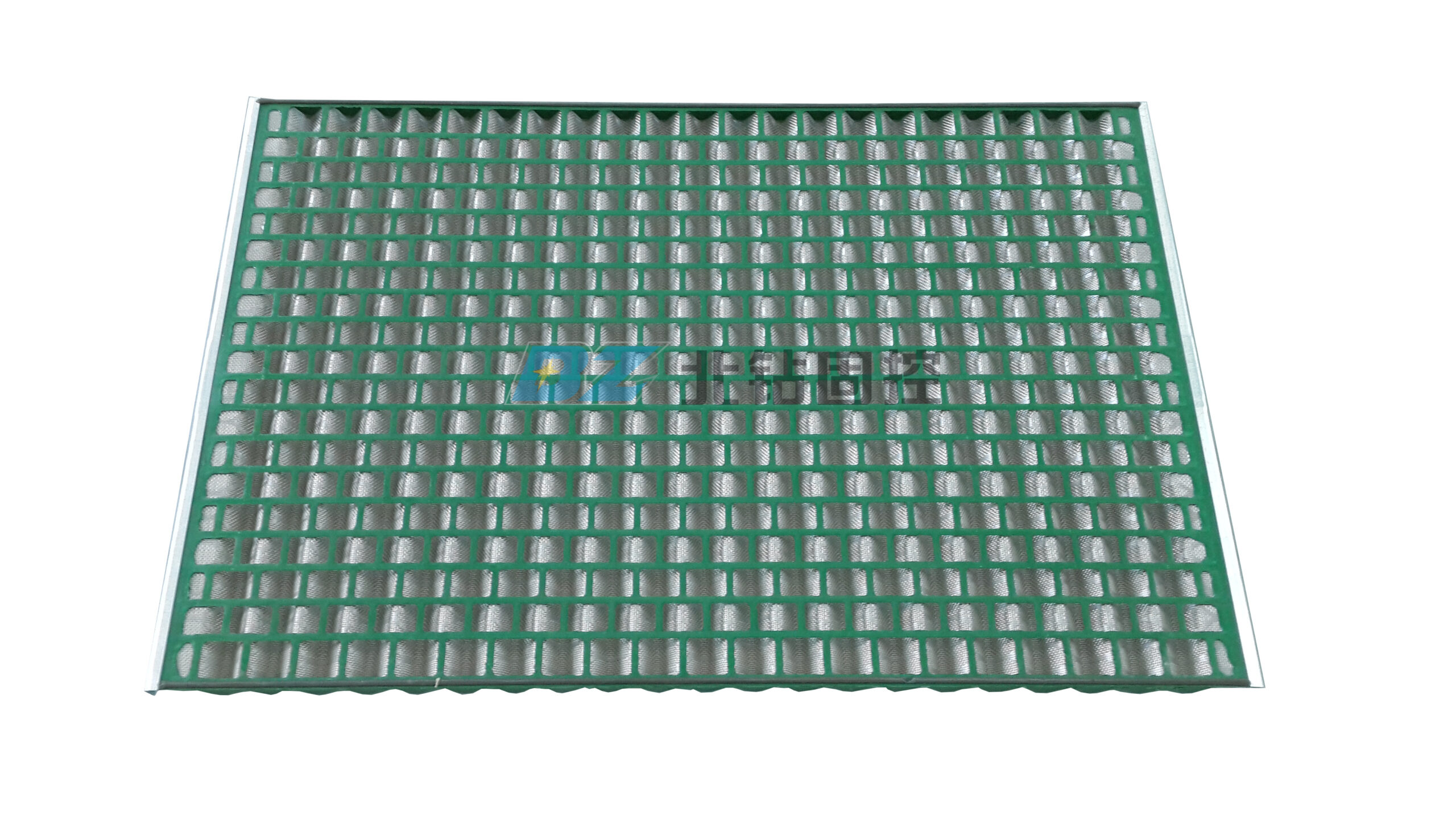

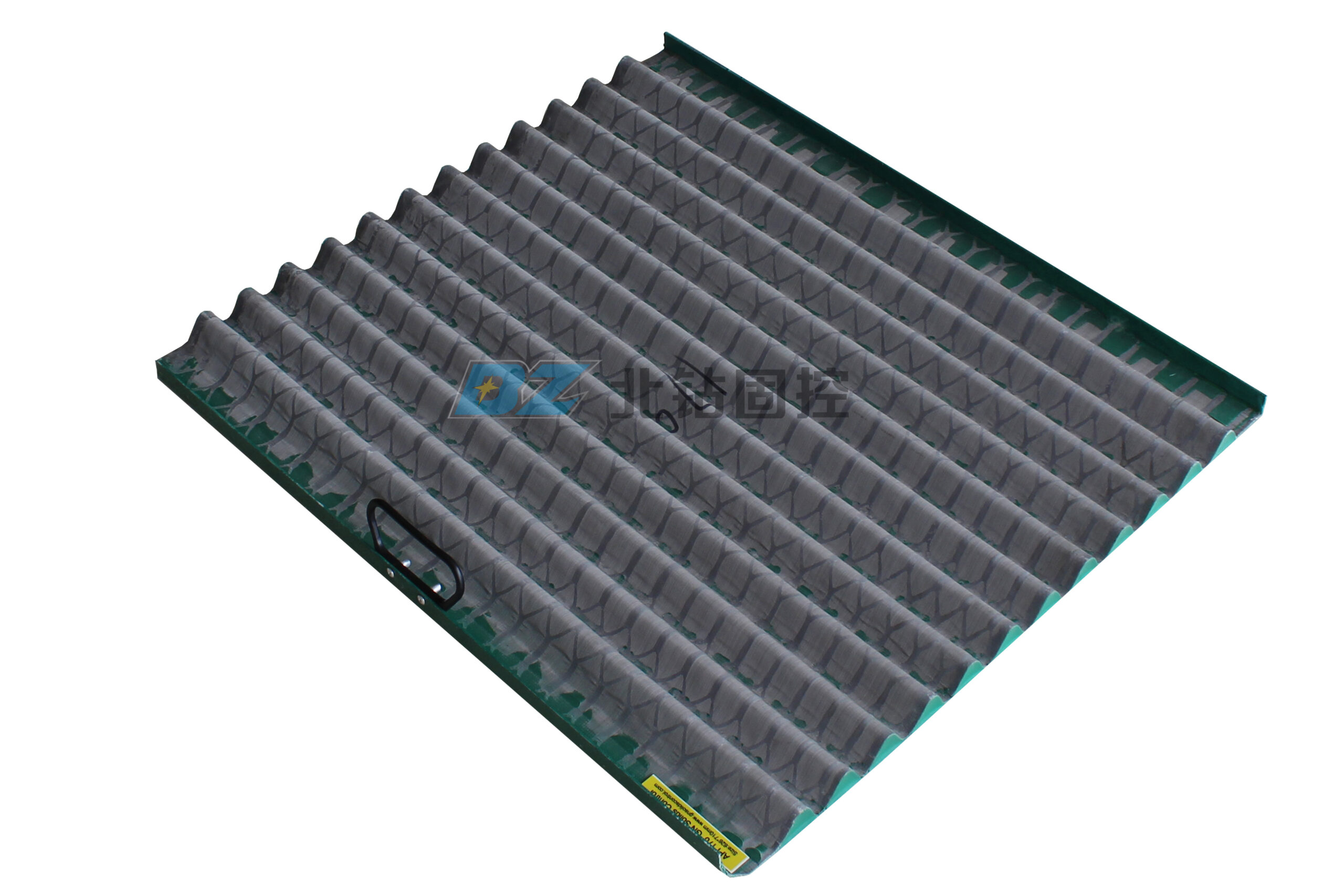

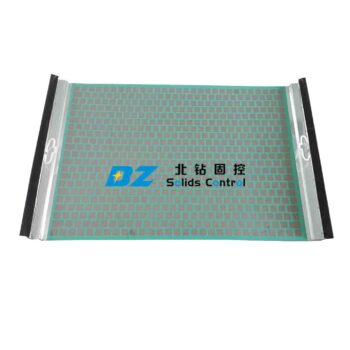

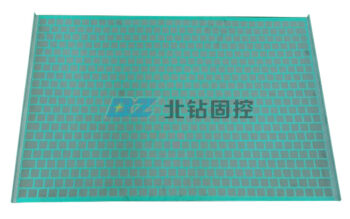

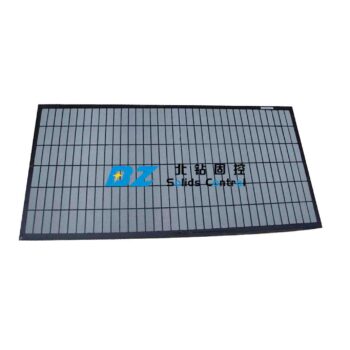

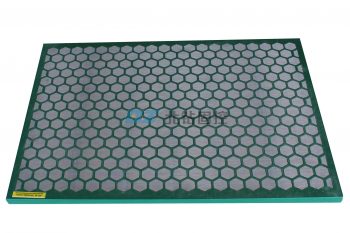

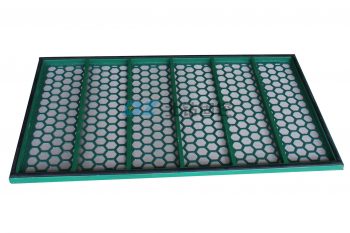

Corrugated replacement shaker screen

Description

Corrugated replacement Shaker Screen has a unique wave shape of the mesh surface, wave type shaker screen mesh is generally composed of 2 or 3 layers of stainless steel 304 or 316 material mesh cloth after composite rolling and bending forming with metal plate with holes.

BZ corrugated replacement screen advantages and characteristics:

1. Large effective filtration area, high drilling fluid processing efficiency.

2. The meshes of each layer of mesh are different, and the accurate and reasonable matching makes the screening effect more detailed.

3. The stainless steel mesh cloth is wavy, and it is tightly bonded with the metal liner. The effective filtering area of the wave screen reaches 125% to 150% of the flat screen of the same size, which greatly increases the processing capacity.

| Mesh | Dimension | Adaptation model |

| 20-325 | 697×1053mm | FLC2000 |

| 20-325 | 695×1050mm | FLC500 |

| 20-325 | 710×626mm | D600 |

| 20-325 | 567×1070mm | D-HYP |

| API Size Parameters | |||

| API Numbe | D 100 Separation(Micron) | API Number | D 100 Separation(Micron) |

| API 20 | >780.0 TO 925.0 | API 100 | >137.5 TO 165.0 |

| API 30 | >550.0 TO 655.0 | API 120 | >116.5 TO 137.5 |

| API 35 | >462.0 TO 550.0 | API 140 | >98.0 TO 116.5 |

| API 40 | >390.0 TO 462..0 | API 170 | >82.5 TO 98.0 |

| API 50 | >275.0 TO 390.0 | API 200 | >69.0 TO 82.5 |

| API 60 | >213.0 TO 275.0 | API 230 | >58.0 TO 69.0 |

| API 70 | >196.0 TO 213.0 | API 270 | >49.0 TO 58.0 |

| API 80 | >165.0 TO 196.0 | API 320 | >41.5 TO 49.0 |

BZ solids control has rich production experience and mature process, according to the customer’s different requirements to produce a variety of specifications of Corrugated replacement Shaker Screen.