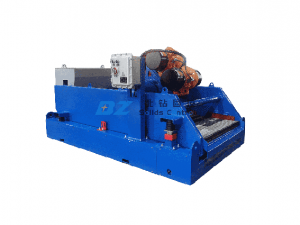

BZ Solids Control Drilling Fluid Shale Shaker working process

Drilling fluid shale shaker is the first stage solid control equipment in drilling mud purification system. It adopts imported vibration motor and is suitable for single, double or triple combination of oil drilling fluid purification. Meanwhile, drilling fluid shale shaker can also be used for bottom flow shaker screen of mud cleaner. BZ solids control drilling fluid shale shaker has high strength, large screening area, adjustable angle of screen box, compact structure, performance is remarkable.At present our company produces the shale shaker is widely used in oil drilling, HDD, TBM,CBM , shale gas drilling, river silt environmental protection and mud purification processing field.

BZ Shale Shaker Structure

Drilling fluid shale shaker is mainly composed of base, screen box, shaker screen, feed tank, excitation motor, damping spring, control switch, regulating device and other parts.

BZ Shale Shaker Working Process

1.Drilling fluid shale shaker is the first stage of solid control equipment in the drilling mud purification system, processing from the drilling bottom of the slurry more than 74 m solid particles.

2.BZ solid control drilling fluid shale shaker is based on the vibration motor under the action of eccentric block force, through the vibration beam to generate linear motion, circular motion or 2-track motion. The angle between the vertical line and the screen of the two motors is formed into an angle A or linear mode. In this way, the two motors rotate in opposite directions, and the excitation force generated by their mutual operation is offset in the X direction, and the excitation force is 0. And two motors in Y direction vibration force each other to drive the whole the reciprocating movement of the screen box up and down along the Y direction, at the same time make the mud on the surface of the mesh along the Y direction is thrown, then free fall has been moving forward, so being thrown down on the mud forward movement, mud slurry through a sieve into the mud tank leakage, and mud in the big screen mesh with perforation sieve out part of the solid particles was, which had mud slurry purification effect.

We are not only equipment focused, but also committing to customized solutions based on your performance requirements and the expectation of your clients. We hope our products will be helpful to your business.