BZ Drilling Waste Treatment System

There are a large number of drilling mud and drilling cuttings in the process of oil exploration and production. The traditional approach is that digging a large pool of mud cycle and making treatment of solidification after completion of drilling. The drilling waste is discharged into the mud pools directly. and then do the harmless treatment such as dosing and mixing etc. Not only higher costs but also longer processing time. But the BZ Drilling Waste Treatment System can solve the problem above. Therefore, The goverment strongly supported the application of drilling waste treatment system.

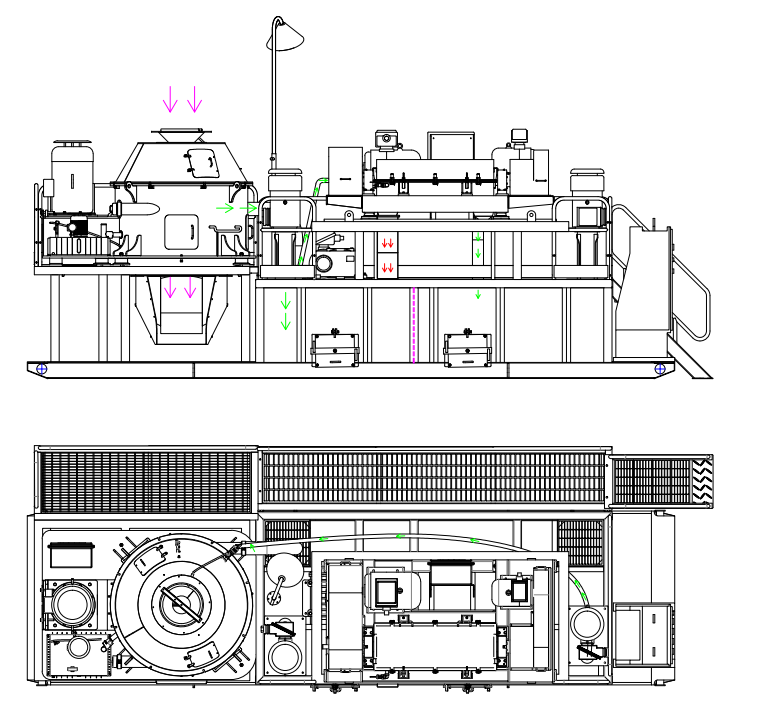

BZ Drilling Waste Treatment Principle is that after realized solid-liquid separation of drilling cuttings, the leachate recovered can be dried by the vertical cuttings dryer . Most of drill cuttings be discharged from the first outlet of cuttings dryer and then The remaining mud will be processed again through the centrifuges. BZ Drilling Waste Treatment System is composed of Vertical Cuttings Dryer,Decanter Centrifuge,tanks and screw conveyor.

Using the drilling waste disposal system , Not only can recycle mud, but also implements treatment on the spot.

2. Cuttings after drying can be used to pave and make bricks.

3. Cuttings after drying can be transport directly and reduce transport costs.